StreamStep

Waste heat recovery from industrial manufacturing

Characteristics

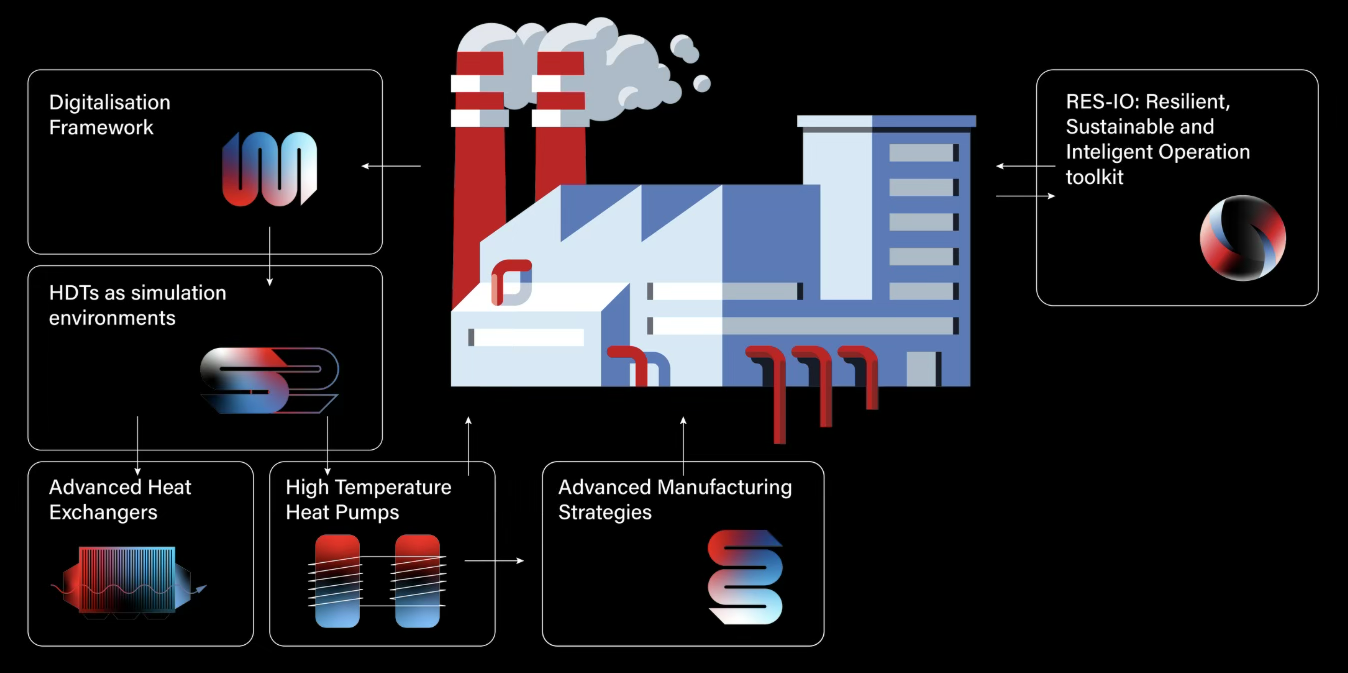

StreamSTEP aims to revolutionise heating energy management in energy-intensive industries by developing and demonstrating advanced solutions for waste heat recovery and reuse. It will deploy five innovative heat exchanger prototypes, operating across a wide temperature range from 135°C to over 1400°C, and high-temperature heat pumps achieving up to 215°C with improved efficiency through ejector technology. Combining advanced manufacturing, novel material alloys, and digitalisation, StreamSTEP integrates data management platforms and hybrid Digital Twin frameworks to optimise process design and operation. Demonstrations will take place in copper, ceramics, silicon, plastics, and oil & gas sectors, leading to higher heat recovery efficiency, greater process flexibility, and a reduced environmental footprint. Funded by the EU’s Horizon Europe programme, StreamSTEP unites 30 partners from across Europe and beyond to drive industrial sustainability and energy efficiency.

Result to be enhanced

StreamSTEP develops and demonstrates integrated solutions for efficient thermal energy recovery and management in energy-intensive industrial processes. The project delivers five prototypes of advanced heat exchangers and high-temperature heat pumps, enabling significant improvements in heat recovery and overall process efficiency. The integration of advanced and additive manufacturing with hybrid digital twin technologies allows optimized design, increased operational flexibility, and reduced costs and environmental impact. The solutions will be validated in five key industrial sectors – copper, ceramics, silicon, plastics, and oil & gas – generating replicable results and supporting the transition toward more sustainable, efficient, and intelligent industrial processes across Europe.

Why is it important?

StreamSTEP is important because it enhances existing industrial processes, making them more sustainable and energy-efficient. The project introduces advanced technologies such as high-temperature heat exchangers and heat pumps that enable the recovery and reuse of thermal energy otherwise wasted, effectively turning waste into a valuable resource. This approach reduces energy consumption and environmental impact without the need to overhaul existing plants or production lines. StreamSTEP demonstrates how technological innovation can complement and improve established industrial processes, supporting the transition toward a greener, more competitive, and environmentally responsible European industry.

Project and Acronym: StreamStep

Call for appication:Horizon Europe

Innovation Cluster to contact: Mesap

Technologies used:Advanced Heat Exchangers (AHX) High Temperature Heat Pumps (HTHP) Advanced Manufacturing Techniques Additive Manufacturing (3D Printing) Hybrid Digital Twin (HDT) Sensor Integration Systems Smart Energy Planning and Management Tools

Lead Company: Gruppo Fos