AKER

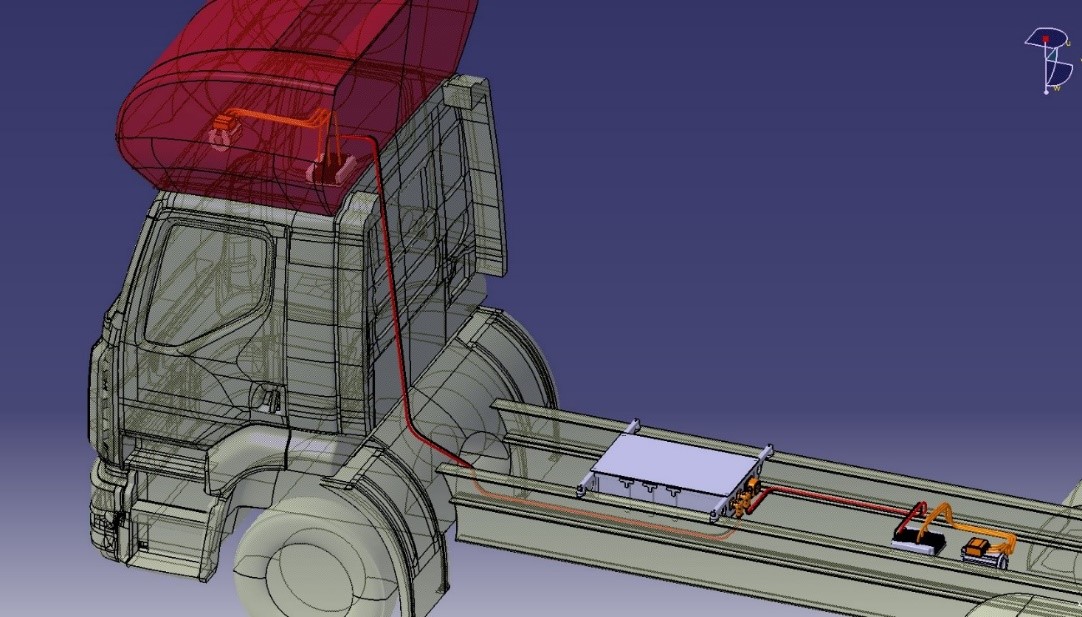

Pilot vehicle for energy recovery

Description

The aim of the AKER project (Aerodynamic Kinetic Energy Recovery) and the research is to acquire, combine, and utilize existing scientific, technological, and commercial knowledge in the field of energy recovery to implement these systems with new energy sources that are not yet available on the market and are not currently considered by manufacturers and body builders of N2 and N3 category trucks. The research has resulted in an innovative pilot vehicle, currently not available on the market, capable of using new energy sources and recovery systems to significantly reduce the fuel consumption, costs, and pollutant emissions of the vehicles mentioned above.

The research imported, technologically adapted and tested energy recovery technologies already consolidated in the automotive sector such as the KERS (Kinetic Energy Recovery System) by applying:

- vehicle pneumo-hydraulic braking assistance;

- energy recovery to replace retarder-type systems, using the generated energy instead of dissipating it as heat.

While the energy recovery system from braking can be considered an established methodology, the use of energy recovery as a replacement for the retarder, integrated into the scheme proposed by the research, is certainly an innovative element. This is because the energy is not dissipated as heat but is instead recovered through the use of an alternator installed on the transmission chain, which generates electrical energy to be stored in a specially inserted and sized battery pack. Alongside these two recovery systems, a third and innovative source of energy recovery, not yet explored in the market, is added: wind energy. The aim of the project and the prototype was to save 8% of fuel per vehicle, resulting in significant environmental and economic benefits. The final tests on the prototype confirmed this objective.

Result to be enhanced

In the heavy industrial vehicle sector, up to now, there are no solutions on the market that can fully achieve the desired economic/environmental results. The research project aims to obtain the following results for the transport services sector and for truck manufacturers and fitters:

- efficiency and rational use of energy, understood as energy recovery and efficient energy management;

- sustainable mobility, understood as the use of powertrains with innovative fuels and technologies/components of propulsion systems for electric mobility (environmental context);

- reduction of fuel costs (economic context and market competitiveness) by using an integrated energy recovery solution that will enable the industrial vehicle to fully reuse and recover the energy generated by its movement.

Why is it important?

The research project idea starts from the analysis of the market and future scenarios that characterize the sector of heavy industrial vehicles used for transporting goods. Manufacturers and fleet fitters are always more interested in new and possible solutions capable of:

1. reduce CO2 emissions

2. reduce consumption

These two objectives derive fundamentally from two current scenarios that will become highly strategic for the market and innovations of heavy industrial vehicles:

1. Since 2015, the EU Commission has adopted a new strategy that aims to reduce fuel consumption and carbon dioxide emissions (for so-called heavy vehicles: trucks and buses). This strategy became necessary because heavy vehicles are responsible for about 1/4 of the CO2 emissions produced by road transport in the European Union and 5% of total climate-changing emissions. Unfortunately, studies conducted by the Commission have shown that between 1990 and 2010, emissions from heavy vehicles increased by 36%, and projections based on a reference scenario with unchanged policies suggest that in the 2030-2050 period, total emissions from heavy vehicles in the EU would remain similar to current levels, which is about 35% higher than those of 1990. This outlook is entirely incompatible with the goal of reducing greenhouse gas emissions from transport by about 60% compared to 1990 levels by 2050, as highlighted in the 2011 Transport White Paper of the Commission and in the Roadmap for a low-carbon economy by 2050. The Commission’s strategy focuses on short-term actions regarding certification, communication, and monitoring of heavy vehicle emissions. This is only an essential first step toward reducing emissions, which will lead the Commission to consider further measures to reduce CO2 emissions from heavy vehicles. The most likely measure is setting binding limits for the average CO2 emissions of newly registered heavy vehicles, as has already been done for light vehicles. The preparatory studies for the strategy indicate that with cutting-edge technologies, it is possible to reduce CO2 emissions from new heavy vehicles by at least 30%.

Project and Acronym: AKER

TRL: ?

Reference call: ?

Innovation Cluster to contact: Clever

Technologies used: Wind energy recovery

Lead company:

Dimsport S.r.l