AGILE

Agile Manufacturing for Competitiveness and Product Innovation

Description

Smart Manufacturing often presents numerous challenges and benefits when applied to traditional sectors such as metalworking, particularly in processes involving the transformation and joining/assembly of metallic components.

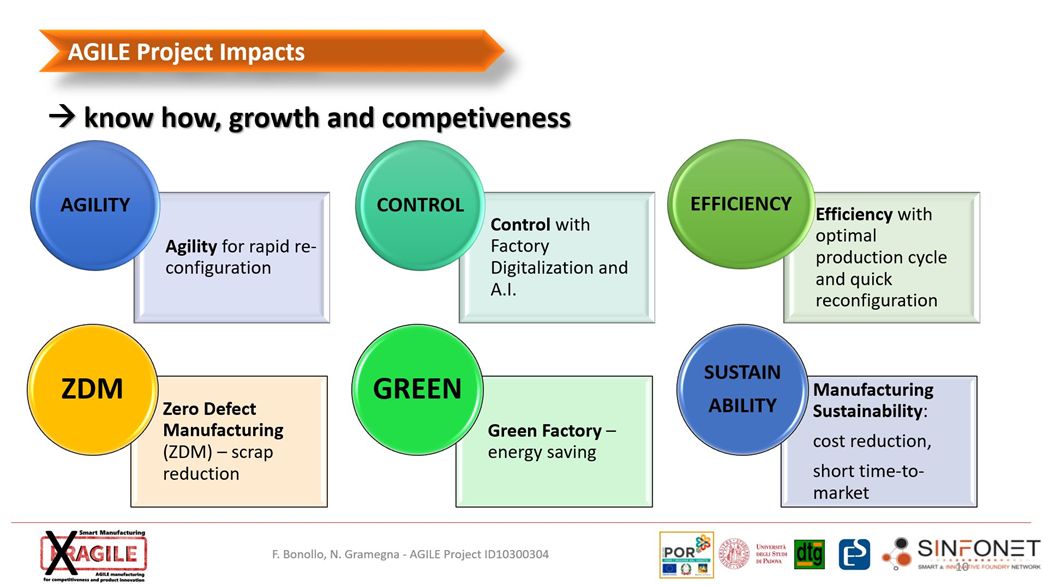

The innovation drivers associated with these technological challenges include environmental sustainability, energy efficiency, agility, and resilience in the face of pandemic restrictions, supported by the enabling technologies typical of Industry 4.0 (e.g., IoT, data mining, AI, additive manufacturing, etc.).

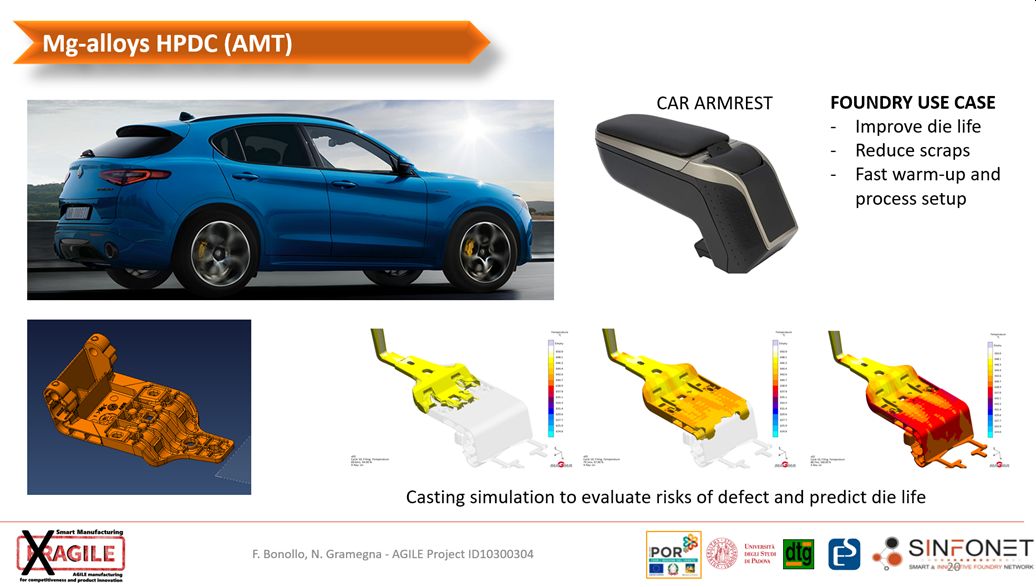

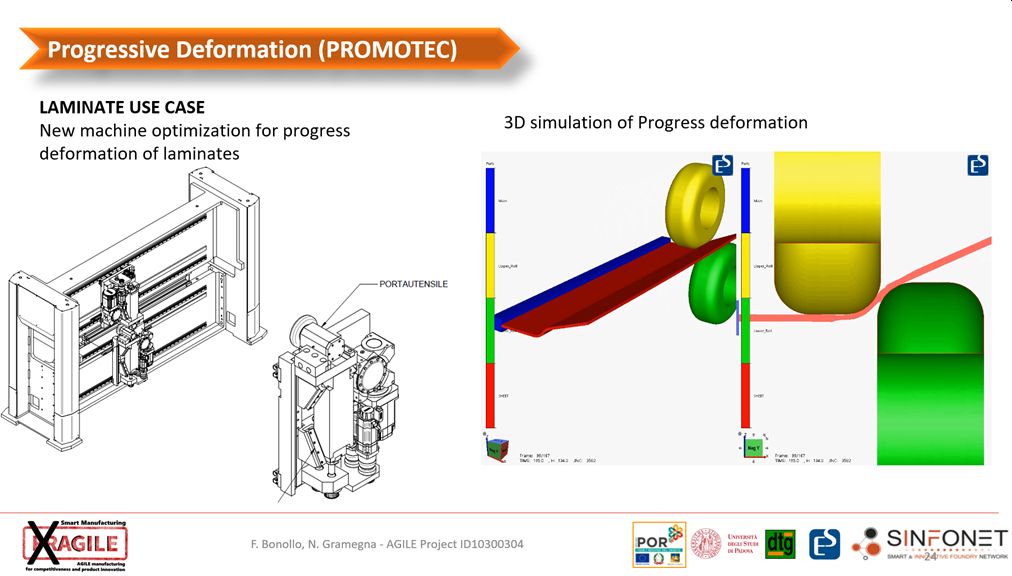

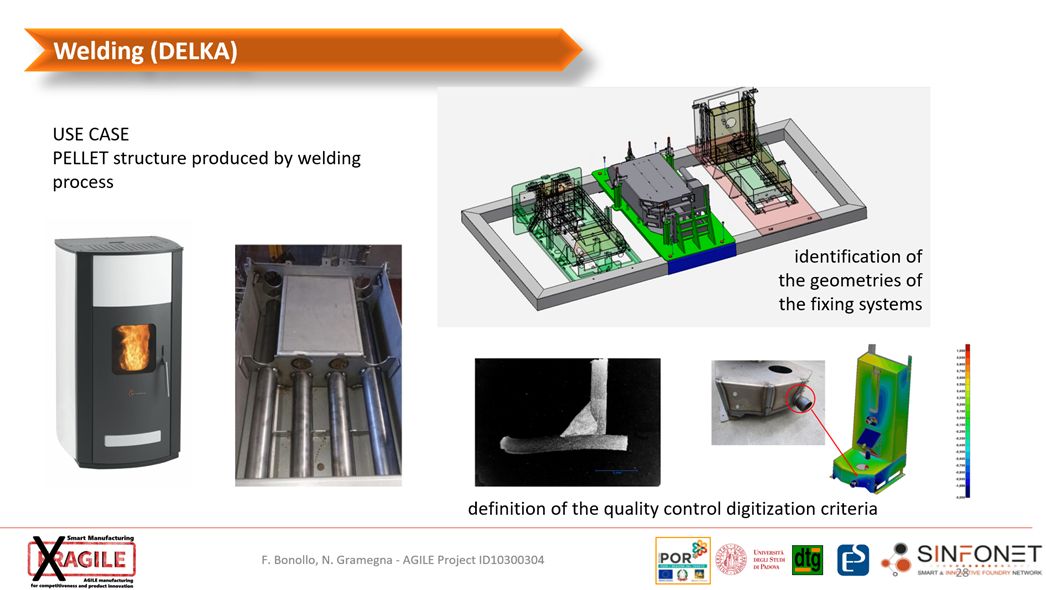

The AGILE project focuses on the experimental development and implementation of enabling technologies across different yet related production sectors, such as aluminium and cast iron foundries, sheet metal deformation, and joining processes like brazing, manual and automated welding.

Why is it important?

The AGILE project demonstrates its potential through real industrial applications, focusing on four areas of intervention:

a. Virtualisation of the design phase: This enables remote management of the design process, minimising in-person activities. It also provides an immediate overview of various production scenarios to better manage competitive recovery conditions, even following partial lockdowns.

b. Development and industrialisation of advanced and rapid production technologies: These technologies are capable of immediately producing goods of sudden and urgent necessity.

c. Rapid reconfiguration and optimisation of production lines: This allows quick modifications to plants and equipment, ensuring the production of conventional or innovative components in small or large batches to address health emergencies. It maximises flexibility and “quick response” capabilities while ensuring competitiveness.

d. Intelligent quality management: Emergency conditions have clearly highlighted how essential the certification of quality and reliability for a new product is to its immediate distribution and availability. This is a crucial tool to develop and implement within companies. Beyond the usual “Zero Defects” challenge, the concept of Agility is introduced to enable rapid reconfiguration of production lines while maintaining robust real-time process control to identify significant deviations.

Project and Acronym: AGILE

Innovation Cluster to contact: Mesap

Lead Company:

EnginSoft S.p.A

www.enginsoft.com | n.gramegna@enginsoft.com